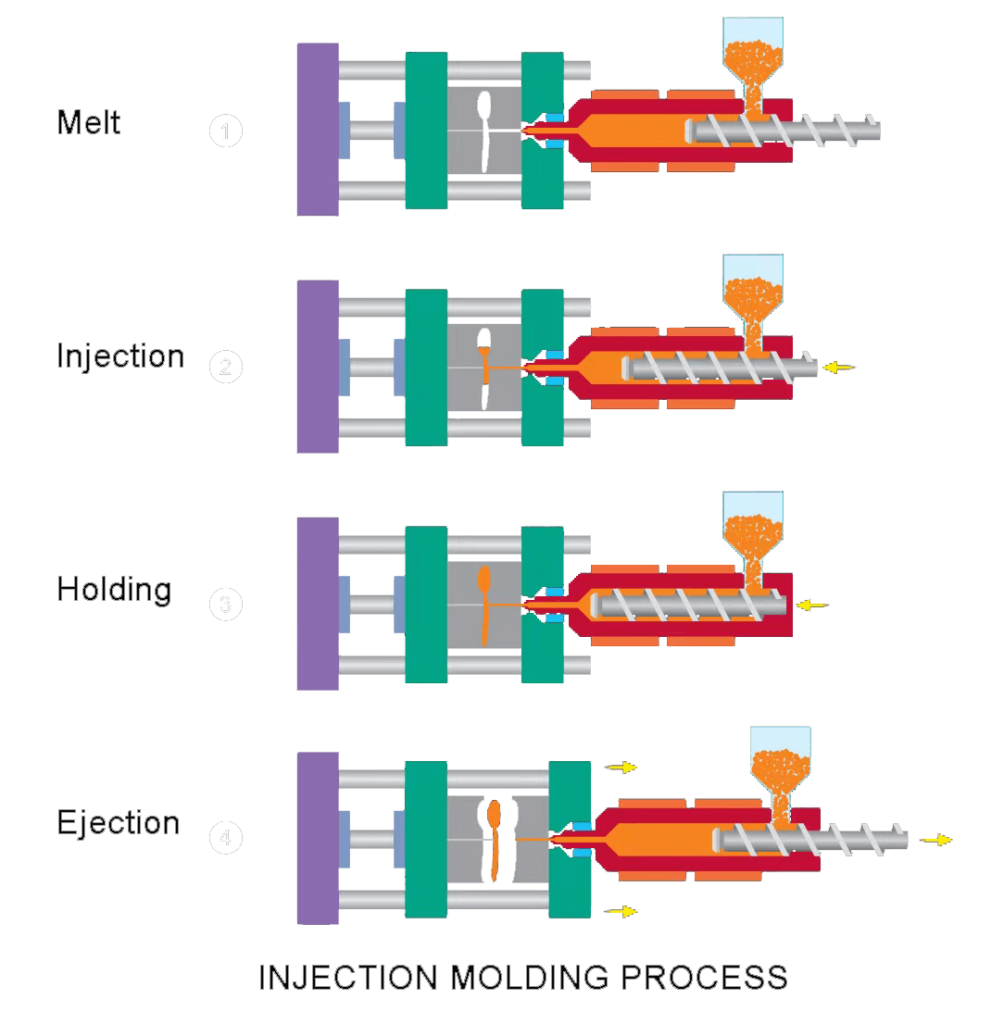

Plastic Moulding Process Examples . in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. Heat melts the plastic, which is mixed. the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. The molten plastic then cools. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. Plastic resin materials enter a barrel. the basic plastic injection molding process consists of the following steps: There are five main steps.

from www.plasticmoulds.net

Plastic resin materials enter a barrel. Heat melts the plastic, which is mixed. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. There are five main steps. the basic plastic injection molding process consists of the following steps: in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion.

Injection Molding Process Topworks Plastic Molding

Plastic Moulding Process Examples in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. There are five main steps. The molten plastic then cools. Heat melts the plastic, which is mixed. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. the basic plastic injection molding process consists of the following steps: when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. Plastic resin materials enter a barrel.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Plastic Moulding Process Examples There are five main steps. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it. Plastic Moulding Process Examples.

From in.pinterest.com

Collapsable Core Plastic injection molding, Mould design, Mechanical Plastic Moulding Process Examples the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. Heat melts the plastic, which is mixed. There are five main steps. Plastic resin materials enter a barrel. the basic. Plastic Moulding Process Examples.

From dxomunhsg.blob.core.windows.net

Plastic Injection Molding Die at Julie Rudolph blog Plastic Moulding Process Examples this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. the basic plastic injection molding process consists of the following steps: when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. There are five main steps. Plastic resin materials enter a barrel.. Plastic Moulding Process Examples.

From unitymanufacture.com

Plastics For Injection Molding Materials And Properties Unity Plastic Moulding Process Examples the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. the basic plastic injection molding process consists of the following steps: in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. this guide explores the types of plastic molding. Plastic Moulding Process Examples.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Plastic Moulding Process Examples plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. the basic. Plastic Moulding Process Examples.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Compression Rutland Plastics Plastic Moulding Process Examples the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. There are five main steps. Heat melts the plastic, which is mixed. in manufacturing, molding refers to the process of shaping. Plastic Moulding Process Examples.

From www.plasticmoulds.net

Injection Molding Process Topworks Plastic Molding Plastic Moulding Process Examples There are five main steps. the basic plastic injection molding process consists of the following steps: Plastic resin materials enter a barrel. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. The molten plastic then cools. the most popular techniques in plastic molding are rotational molding, injection. Plastic Moulding Process Examples.

From www.vrogue.co

Plastic Injection Molding Manufacturing Process Funda vrogue.co Plastic Moulding Process Examples There are five main steps. Plastic resin materials enter a barrel. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. Heat melts the plastic, which is mixed. The. Plastic Moulding Process Examples.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Plastic Moulding Process Examples this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. the basic plastic injection molding process consists of the following steps: the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. in a nutshell, plastic moulding is the process of creating plastic parts. Plastic Moulding Process Examples.

From rangechange.ca

Separato ossigeno plastic mold manufacturing process Idealmente Plastic Moulding Process Examples the most popular techniques in plastic molding are rotational molding, injection molding, blow molding, compression molding, extrusion. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. The molten plastic then cools. in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould.. Plastic Moulding Process Examples.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Plastic Moulding Process Examples this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. the. Plastic Moulding Process Examples.

From mavink.com

Injection Molding Process Plastic Moulding Process Examples Heat melts the plastic, which is mixed. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. The molten plastic then cools. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. There are five main steps. this. Plastic Moulding Process Examples.

From cncmachiningservicechina.blogspot.com

CNC Machining Service China Company FIVE BASIC REQUIREMENTS OF PLASTIC Plastic Moulding Process Examples The molten plastic then cools. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. Plastic resin materials enter a barrel. the most popular techniques in plastic molding are rotational molding, injection. Plastic Moulding Process Examples.

From www.plasticmoulds.net

Various Plastic Molding Process Plastic Moulding Process Examples in a nutshell, plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. Heat melts the plastic, which is mixed. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. this guide explores the types of plastic molding processes, compares their characteristics,. Plastic Moulding Process Examples.

From mavink.com

Types Of Molding Process Plastic Moulding Process Examples in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. The molten plastic then cools. Plastic resin materials enter a barrel. There are five main steps. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. the basic. Plastic Moulding Process Examples.

From hxejguvaj.blob.core.windows.net

Pvc Rubber Mould Price at Ann Huff blog Plastic Moulding Process Examples the basic plastic injection molding process consists of the following steps: this guide explores the types of plastic molding processes, compares their characteristics, and provides insights into. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. the most popular techniques in plastic molding are rotational molding,. Plastic Moulding Process Examples.

From protomouldplastics.co.uk

The Process of Plastic Injection Moulding Protomould Plastics Plastic Moulding Process Examples Plastic resin materials enter a barrel. when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. in manufacturing, molding refers to the process of shaping a type of pliable material or liquid by using a rigid. the most popular techniques in plastic molding are rotational molding, injection molding,. Plastic Moulding Process Examples.

From in.pinterest.com

Collapsable Core Plastic injection molding, Mould design, Mechanical Plastic Moulding Process Examples when a plastic product is produced, it can be formed by 1 of 7 different plastic manufacturing methods including:. plastic moulding is a process of manufacturing plastic products by melting plastic material and injecting it into a mould. Plastic resin materials enter a barrel. There are five main steps. the most popular techniques in plastic molding are. Plastic Moulding Process Examples.